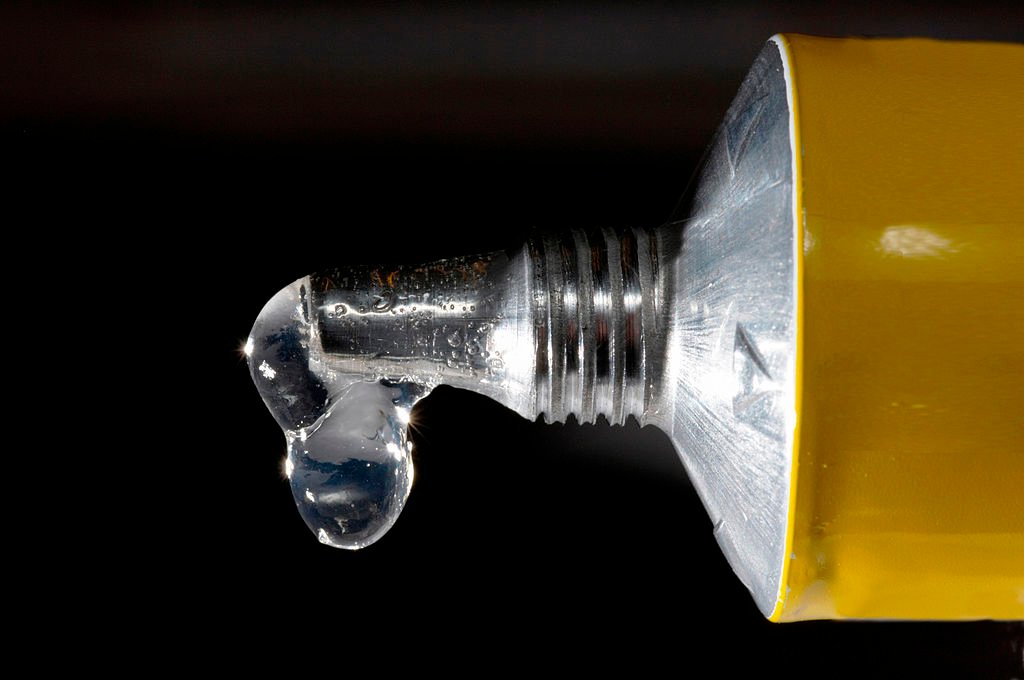

Researchers have developed a groundbreaking sustainable adhesive made from used cooking oil, transforming common kitchen waste into a high-performance glue with strength that rivals and even surpasses many commercial adhesives. By chemically breaking down the triglycerides in waste oil and reassembling them into long-chain polyester polymers, scientists at the University of South Carolina created a material that can bond metals, wood, and cardboard with exceptional durability. This innovation not only offers a greener alternative to petroleum-based plastics and adhesives but also highlights the untapped potential of biomass waste as a renewable feedstock for advanced materials.

Tested in real-world scenarios, the cooking-oil-derived glue demonstrated surprising capabilities—holding up to 270 pounds and even successfully towing a mid-size car uphill when used between steel plates. It can also be molded into stick form for use in hot glue guns, making it practical for everyday applications from crafts to industrial assembly. With millions of gallons of used cooking oil generated worldwide each year, this breakthrough represents a significant step toward a circular economy for plastics and adhesives.

Waste Oil’s Journey from Fryer to Polymer

Cooking oil, composed predominantly of long hydrocarbon chains in the form of triglycerides, is notoriously difficult to dispose of responsibly. Left unchecked, it contributes to environmental issues when poured into waterways or landfills. However, researchers have found that by chemically converting the fatty acids and glycerol in used cooking oil into simpler monomers, they can repurpose waste into building blocks for durable polymers.

These monomers are then reassembled into polyesters that closely mimic low-density polyethylene (LDPE)—a common plastic used in packaging and consumer products. Unlike conventional plastics, these materials can be readily broken down and recycled under mild conditions, integrating smoothly into sustainable material cycles.

Record-Setting Strength and Versatility

One of the most striking features of the new glue is its mechanical performance. In laboratory tests, steel plates bonded with the cooking-oil adhesive remained joined while being used to tow a sedan up a slope, a feat few conventional glues can achieve. The adhesive also performed favorably on a variety of other surfaces, including copper, softwood, and cardboard.

The versatility of the material means it could replace or augment many current adhesive types—especially where strength, flexibility, and recyclability are priorities. It offers an eco-friendly alternative in applications ranging from packaging and automotive components to electronics, medical devices, and laminate products.

Sustainable Synthesis and Circular Impact

Importantly, the synthesis process converts what would otherwise be discarded oil into biodegradable and recyclable polymers, aligning with circular-economy principles. Scientists emphasize that waste cooking oil—estimated in the billions of gallons annually—represents an abundant, renewable resource that can help reduce reliance on fossil fuels in plastics and adhesives manufacturing.

Moreover, the process can be tuned: by adjusting the polymer chains’ structure (linear vs. branched), researchers can produce materials with varied mechanical properties, from rigid plastics to flexible adhesives, further broadening the technology’s potential.

Practical Applications and Future Potential

Because these polyester materials can be remelted, recycled, and even blended with conventional plastics, their adoption could help decrease the environmental footprint of many industries. Packaging, often a major source of plastic waste, stands out as an area where this innovation could have immediate impact.

Additionally, the glue’s manufacturability into hot-melt sticks and adaptability across substrates positions it as a contender for widespread commercial use, potentially replacing traditional adhesives in both consumer and industrial contexts.

Environmental and Economic Implications

Repurposing cooking oil into high-value adhesives encapsulates the essence of value-added waste innovation—turning environmental liabilities into marketable, sustainable products. With increasing regulatory and consumer pressure to reduce plastic pollution, this technology could offer both ecological and economic benefits.

By reducing dependency on virgin fossil feedstocks, materials like this cooking-oil glue help advance a more resilient, diversified materials ecosystem. The technology may also spur further research into waste-to-materials processes using other biomass streams, accelerating the transition away from petrochemical-centered production.

The transformation of waste cooking oil into a glue strong enough to tow a car is more than a novelty—it’s a paradigm shift in how we view waste and materials science. This innovation underscores that sustainability and performance need not be mutually exclusive; eco-friendly materials can outperform their conventional counterparts when science is applied creatively. As industries and consumers alike seek greener alternatives, breakthroughs like this demonstrate that everyday waste streams can be powerful resources for building the products of tomorrow. However, realizing the full environmental promise of this technology will require scaling production, establishing recycling pathways, and integrating these materials into existing supply chains. If successful, this could mark a major step toward reducing our reliance on fossil fuels and reshaping global plastics and adhesives markets for the better.

Jan loves Wildlife and Animals and is one of the founders of Animals Around The Globe. He holds an MSc in Finance & Economics and is a passionate PADI Open Water Diver. His favorite animals are Mountain Gorillas, Tigers, and Great White Sharks. He lived in South Africa, Germany, the USA, Ireland, Italy, China, and Australia. Before AATG, Jan worked for Google, Axel Springer, BMW and others.