It sounds like a magic trick: a solid tile, no moving parts, silently turning warmth into watts. But this isn’t stagecraft – it’s the long-maturing science of heat-to-electricity conversion stepping into the spotlight. In a world where factories, engines, and even our own bodies shed oceans of wasted heat, the promise is tantalizing: harvest what we already throw away. The newest devices are smaller, tougher, and smarter about turning temperature into power, and they’re beginning to slip into places batteries and turbines struggle. The big question isn’t whether it works – it’s how far we can push it.

The Hidden Clues

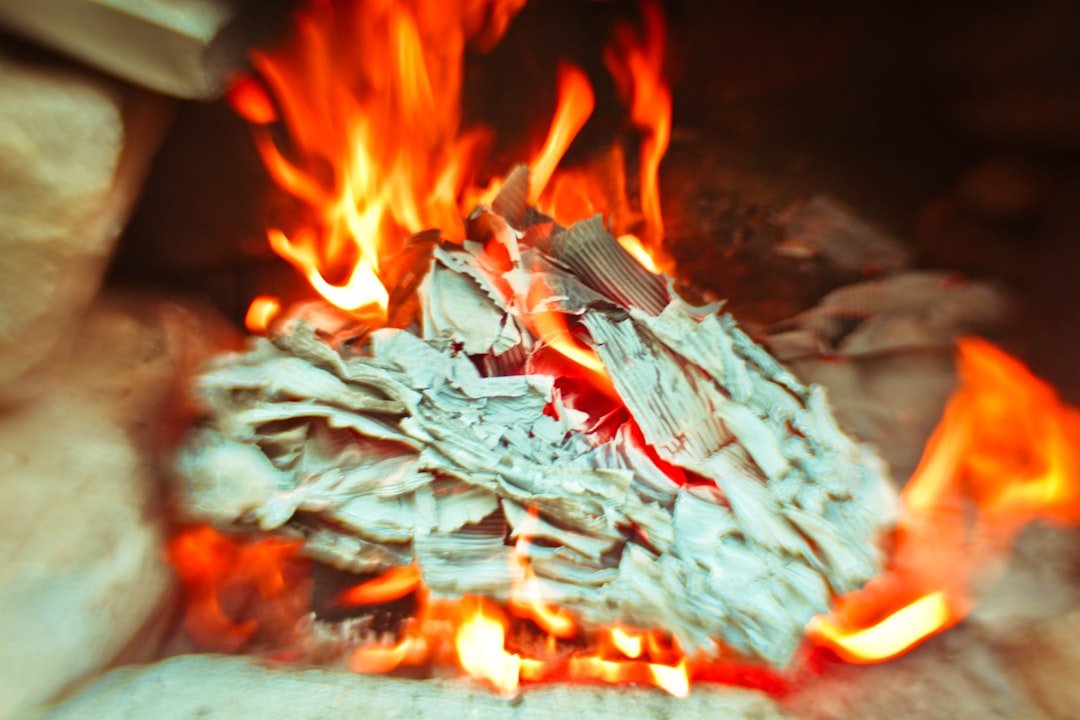

Heat is the energy we tend to ignore, the background hiss behind brighter headlines about wind and solar. Yet every car tailpipe, server farm, and industrial kiln spills useful energy as warmth, much of it drifting into the air. Engineers have long calculated that roughly about two thirds of fuel’s original energy can end up as waste heat in conventional engines and power plants. That means opportunities lurk at almost every hot surface, from a steam pipe to a pizza oven.

The modern twist is control. By pairing a heat source with materials that respond to temperature differences, you can create a steady stream of electrical charge without a single gear or blade. No combustion chamber, no steam cycle, no delicate bearings – just gradients and clever physics. It feels almost subversive, like salvaging coins from under the couch cushions and realizing there’s a small fortune hiding there.

From Ancient Tools to Modern Science

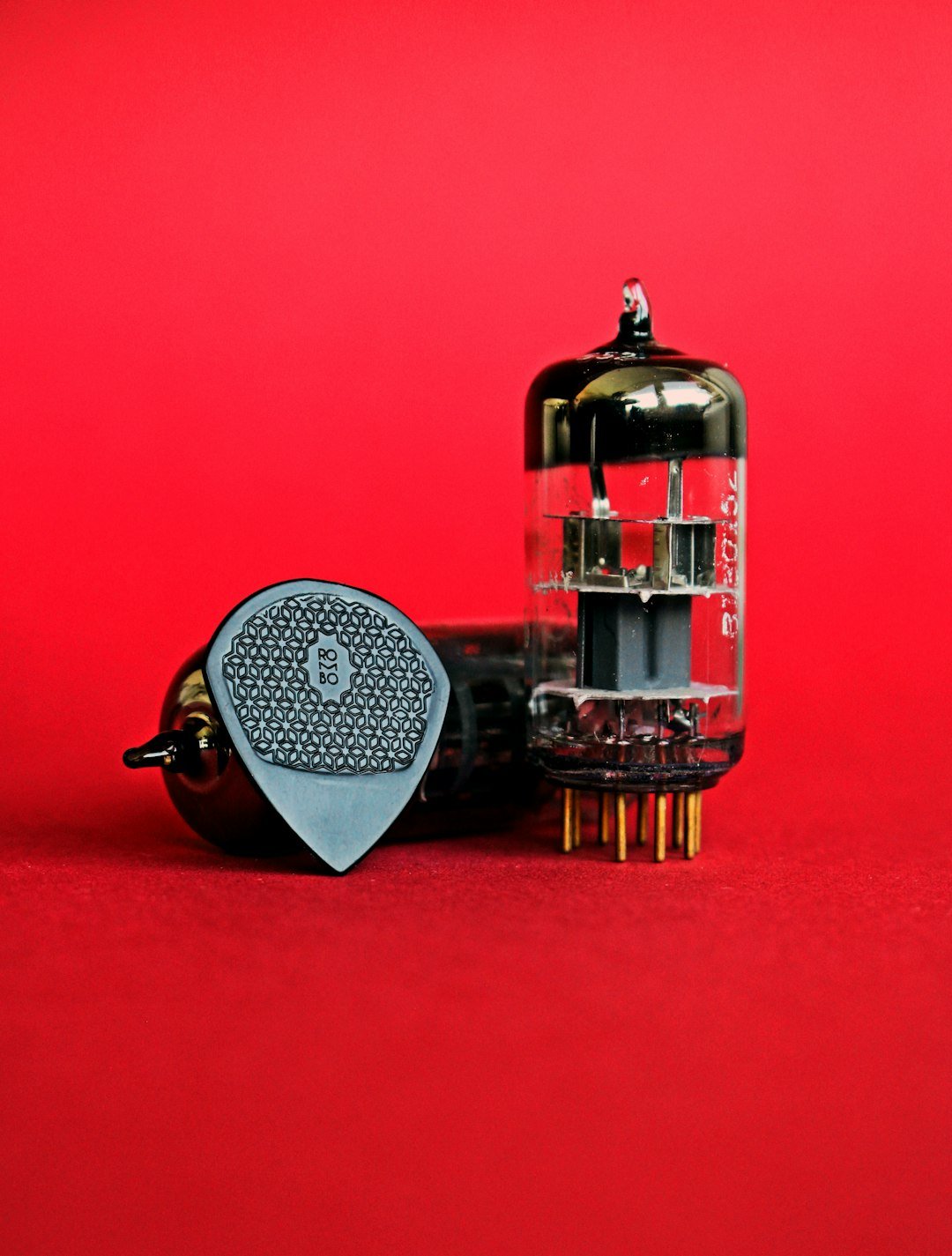

The basic effect behind many of these devices dates to the early nineteenth century, when scientists discovered that a temperature difference across certain materials could nudge electrons into motion. Those humble thermocouples evolved into sensors we still use today to measure temperature in everything from stoves to spacecraft. Later, space missions relied on radioisotope thermoelectric generators – steady heat sources matched with thermoelectric materials – to power probes far from the Sun.

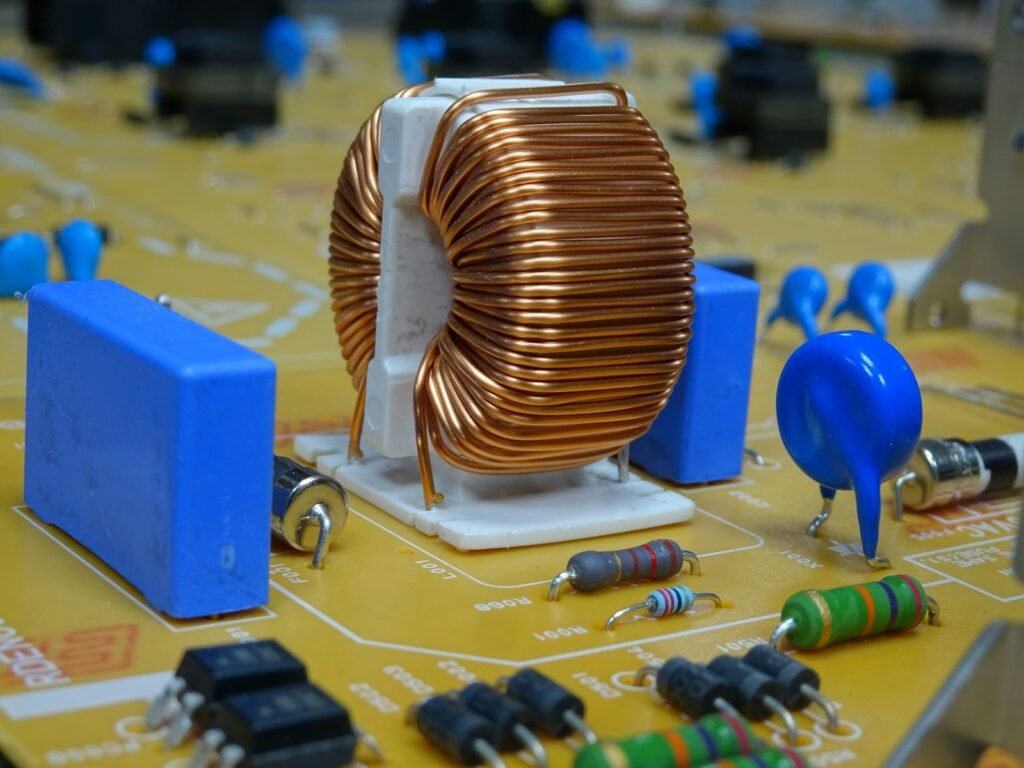

What’s new is precision and scale. Decades of work in materials science have upgraded those early concepts into layered semiconductors, nanostructures, and photonic surfaces that treat heat like a sculptor treats clay. We’ve learned to train vibrations and photons, blocking what we don’t want and channeling what we do. The result is a family of devices – thermoelectrics, thermionic converters, and thermophotovoltaics – that speak the same language of heat, just with different accents.

Inside the Physics

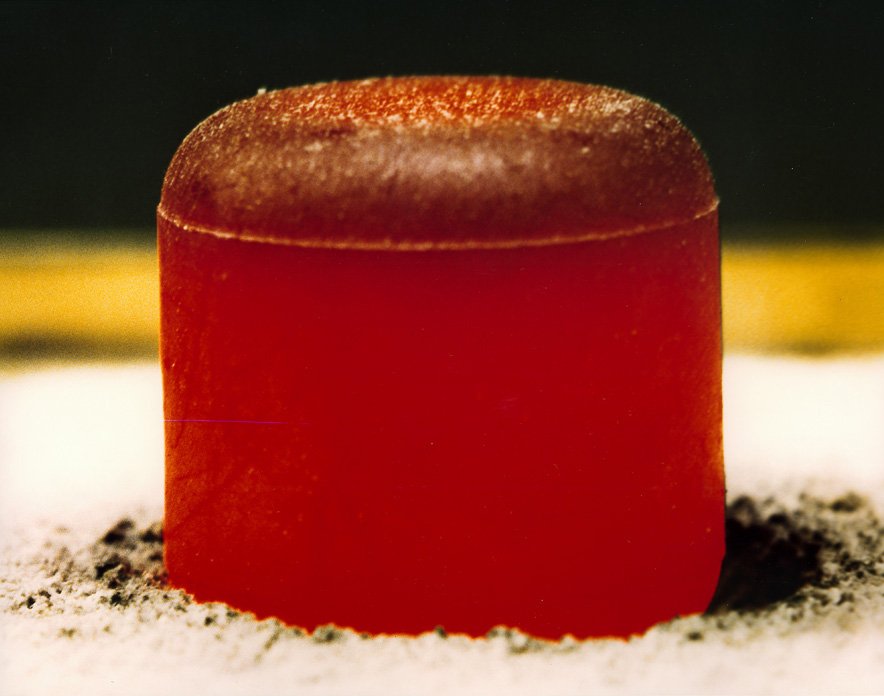

Most people first meet this idea through the Seebeck effect: put two dissimilar materials together, hold one side hotter than the other, and an electrical voltage appears. At the microscopic level, heat jostles charge carriers, and if you give them a preferred direction – hot on one side, cool on the other – they drift in a way that can be tapped as current. The efficiency rides on a metric called the figure of merit, which is boosted when a material conducts electricity well but keeps heat from leaking through too easily. That subtle balance has driven decades of research into compounds like bismuth telluride, skutterudites, half-Heuslers, and tin selenide.

Other approaches flip the script. Thermophotovoltaic cells let a hot surface glow like a miniature sun, and a specially tuned photovoltaic cell turns that glow into electricity with remarkable efficiency. Thermionic converters, meanwhile, use heat to fling electrons across a tiny gap, catching them on the far side like a charge net. There’s even nighttime power from radiative cooling, where a device uses the cold of outer space as a heat sink to pull a faint but continuous trickle of electricity after sunset. Different routes, one destination: electricity from nothing but heat.

The Prototype on the Bench

Picture a ceramic tile the size of a coaster clamped to a warm exhaust line in a workshop. One face feels toasty, the other is cooled by a small finned heat sink, and the device’s leads run to a thumbnail-sized power board that smooths the trickle into a steady output. A sensor blinks alive and posts data to a phone – no battery swap, no charging downtime, just the pipe’s heat doing the work.

In these small setups, output ranges from milliwatts to a few watts, depending on temperature difference, module size, and how well the cooling is handled. Put enough modules in series and you can run more than sensors – signage, lighting, or a tiny pump can all be in reach. I once strapped a pocket generator onto a camping stove just to see if it could push a radio beacon, and it did, though barely; the lesson was clear: design the thermal plumbing well and the electricity follows. Scale that thinking to industrial ducts or high-temperature storage, and the math gets a lot friendlier.

Why It Matters

This is a quiet revolution in places where conventional machinery stumbles. Batteries are wonderful, but they wear out, hate heat, and require maintenance cycles that don’t suit remote or harsh sites. Turbines deliver big power at scale, but they need moving parts, lubrication, and safety systems that add cost and complexity. Solid-state heat harvesters just sit and work, converting a gradient into useful electrons like a leaf turns light into sugar.

The implications ripple outward. Capturing even a small fraction of industrial waste heat can trim fuel use and lower emissions without waiting for a complete overhaul of equipment. For sensors in pipelines, railways, and chemical plants, heat-powered nodes mean fewer truck rolls and longer lifetimes. In emergencies, a device that wakes up whenever something is warm – body heat, a cooktop, a generator casing – can keep critical communications or monitoring alive. It’s not a silver bullet, but it’s a sharp, reliable tool.

Global Perspectives

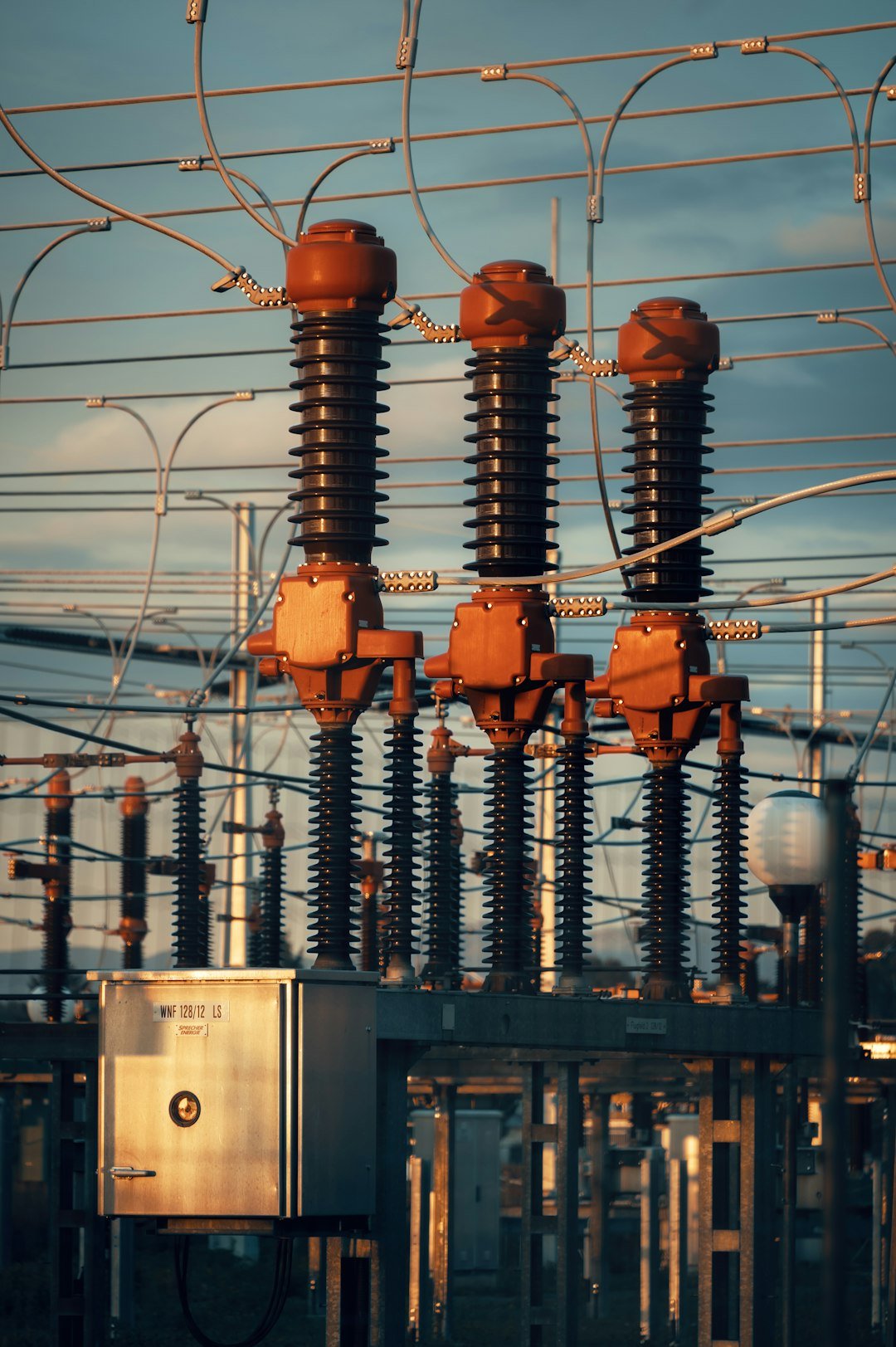

Heavy industry – cement, steel, glass, chemicals – operates at temperatures where today’s devices can sip power comfortably. In regions where grid stability is shaky, scavenging electricity from existing heat sources can keep clinics’ data loggers, vaccine fridges’ monitors, and rural internet relays online when outages strike. Cities, too, leak heat through district systems and data centers, offering distributed sites to power dense networks of sensors that make infrastructure smarter and safer.

Developing markets stand to benefit from cookstove attachments that light homes or charge phones, using the same fire that cooks dinner. On the other end of the spectrum, spacecraft and remote polar stations gain rugged, low-maintenance power where batteries falter and fuel logistics are brutal. When energy access is uneven, a technology that rides along with heat already present can level the field in small, meaningful ways. That mix of high-tech materials and simple value – use what’s there – makes the story feel universal.

The Future Landscape

Efficiency is the lodestar. In thermoelectrics, researchers are pushing materials whose performance approaches about three on the figure-of-merit scale in carefully designed conditions, a milestone that once seemed out of reach. In thermophotovoltaics, purpose-built cells matched to white-hot emitters have demonstrated conversion efficiencies on the order of what traditional steam cycles deliver, but in a compact, solid-state form. That opens the door to “thermal batteries” that store intermittent renewable energy as heat and dispatch electricity on demand.

Cost and durability run close behind. Manufacturable thin films, recyclable alloys, and robust interconnects must survive years of thermal cycling without cracking or drifting out of spec. Power electronics will keep getting smarter at squeezing useful voltage from tiny temperature differences, turning dribbles into steady streams. Expect hybrid systems – heat harvesters topping up batteries, or TPV units paired with heat pumps and smart controls – to show up in factories first, then fan out to commercial buildings. When policy leans in with waste-heat incentives and performance standards, adoption tends to move from pilot to practice.

Simple Ways to Engage

Start by noticing heat, the way you notice sunlight after a storm. Feel the back of your refrigerator, the warmth from your laptop charger, the exhaust from a café kitchen, and imagine a little device skimming power from it. That shift in attention – seeing heat as a resource – changes how we talk about energy at home, at work, and in city planning. If you work in facilities or manufacturing, ask vendors about waste-heat recovery options and request pilots for powering sensor networks.

Support research teams and nonprofit programs that advance materials, reliability testing, and open standards for energy-harvesting sensors. Choose products that use energy harvesting where it fits – wireless thermostats, pipeline monitors, or industrial beacons designed to run on heat. Encourage local leaders to include waste-heat mapping in climate action plans, because what gets mapped gets managed. And if you tinker, try a safe, small demo kit on a coffee mug or radiator: there’s nothing quite like watching a tiny LED light up from nothing but heat.

Suhail Ahmed is a passionate digital professional and nature enthusiast with over 8 years of experience in content strategy, SEO, web development, and digital operations. Alongside his freelance journey, Suhail actively contributes to nature and wildlife platforms like Discover Wildlife, where he channels his curiosity for the planet into engaging, educational storytelling.

With a strong background in managing digital ecosystems — from ecommerce stores and WordPress websites to social media and automation — Suhail merges technical precision with creative insight. His content reflects a rare balance: SEO-friendly yet deeply human, data-informed yet emotionally resonant.

Driven by a love for discovery and storytelling, Suhail believes in using digital platforms to amplify causes that matter — especially those protecting Earth’s biodiversity and inspiring sustainable living. Whether he’s managing online projects or crafting wildlife content, his goal remains the same: to inform, inspire, and leave a positive digital footprint.