Unlocking New Reactions in Microbial Factories (Image Credits: Unsplash)

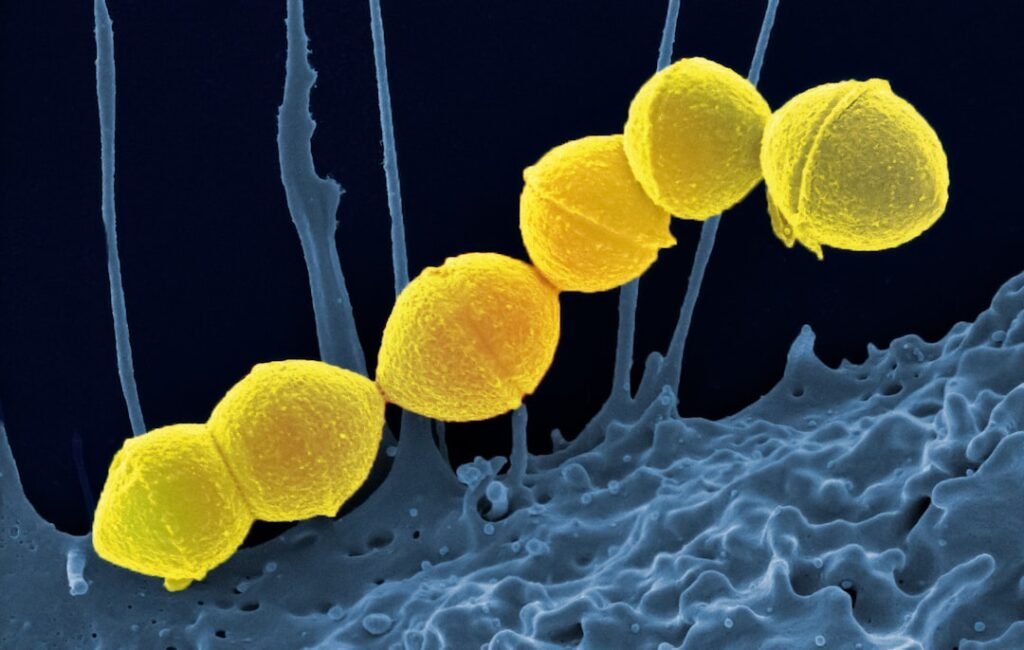

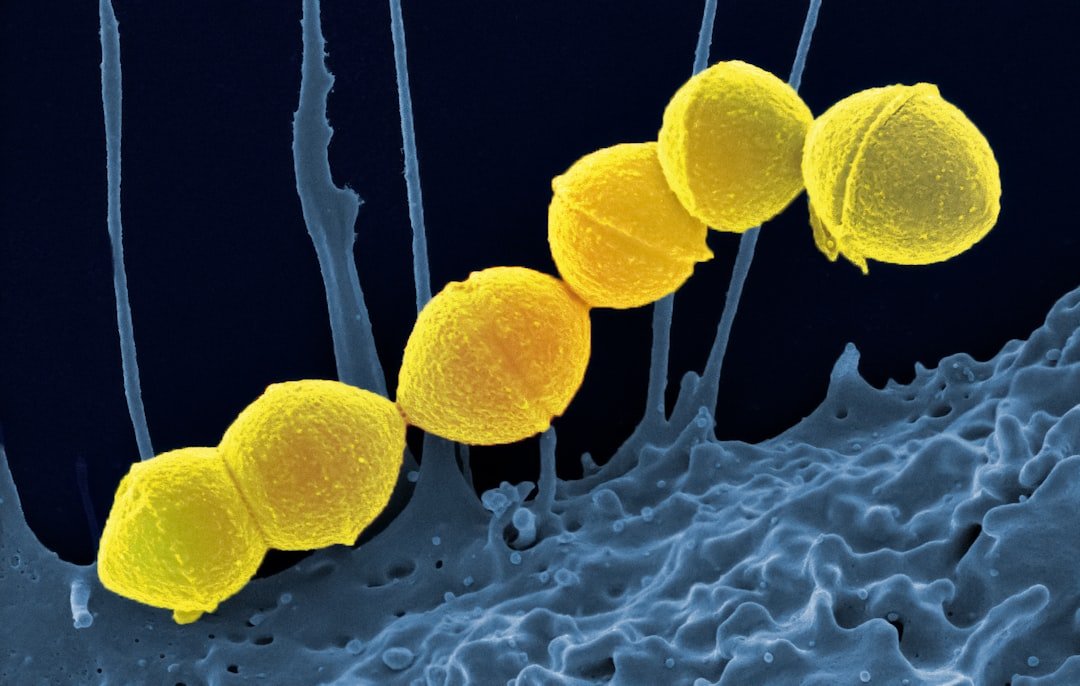

Urbana-Champaign, Illinois – Scientists have engineered the common bacterium Escherichia coli to produce novel molecules by activating chemical reactions with light inside living cells.[1][2]

Unlocking New Reactions in Microbial Factories

A team led by Huimin Zhao at the Carl R. Woese Institute for Genomic Biology demonstrated this advance in a study published in Nature Catalysis. The researchers reprogrammed E. coli’s cellular machinery to perform photoenzymatic reactions, which rely on light to trigger enzymes that form carbon-carbon and carbon-nitrogen bonds.[3]

Traditional enzymes excel at selectivity but limit biomanufacturing to a narrow range of reactions. Photoenzymes overcome this by combining photocatalysis with biocatalysis, enabling transformations previously inaccessible to biology or challenging for chemistry. Zhao’s group previously showed such reactions worked outside cells, but this marked the first integration into living metabolism.[1]

The platform targeted three key reaction classes: hydroalkylations, hydroaminations, and hydroarylations. These processes generate free radical intermediates that forge new bonds under illumination. Without light, the enzymes remained dormant, adding precise control to the system.

Seamless Integration Inside the Cell

Led by first author Yujie Yuan, the team used synthetic biology to equip E. coli with all necessary components. The bacteria produced photoenzymes, radical precursors, and substrates internally, converting simple glucose into complex products without external additives.[2]

This self-contained design turned whole cells into catalytic chassis. Yuan noted, “We don’t need to feed in any radical precursors, and the E. coli can produce the photoenzymes, radical precursors, and the substrates in the whole cells together.”[3]

- Hydroalkylation: Adds alkyl groups to form C-C bonds.

- Hydroamination: Incorporates amines for C-N linkages.

- Hydroarylation: Links aryl groups via radical mechanisms.

The system proved versatile across six distinct photoenzymatic reactions, confirming broad compatibility.

Scaling Up Amid Technical Hurdles

Researchers tested scalability by running four reactions in a bioreactor. The experiments succeeded beyond lab flasks, validating potential for larger production.[1]

However, product titers stayed low due to demands for controlled light and anaerobic conditions. Standard bioreactors lack features for uniform illumination, complicating optimization. Yuan highlighted, “For the photoenzymatic reactions, the reaction conditions are restricted by the process. Light and also anaerobic conditions are needed. It is a major challenge to determine the conditions in the bioreactor.”[2]

The team now collaborates with industry on custom reactors to improve light distribution and data collection.

A Greener Path for Pharmaceuticals and Beyond

This proof-of-concept expands biomanufacturing’s chemical repertoire toward pharmaceuticals and herbicides. Microbes could replace multi-step chemical syntheses with efficient, light-driven processes using cheap feedstocks.

Zhao described the impact: “This is a proof-of-concept. It demonstrates it is possible to incorporate engineered enzymes with new-to-nature reactivity into cellular metabolism and produce compounds that cannot be produced by biological approaches or even chemical approaches, at least in the past.”[3]

| Approach | Advantages | Limitations |

|---|---|---|

| Traditional Biomanufacturing | High selectivity, sustainable | Narrow reaction scope |

| Photoenzymatic | New bonds, light control | Scale-up challenges |

Key Takeaways

- First in vivo photoenzymatic biosynthesis in microbes.

- Versatile platform supports multiple radical-based reactions.

- Paves way for sustainable production of drugs and agrochemicals.

This breakthrough positions photobiocatalysis as a transformative tool for sustainable chemistry, bridging biology and light to access untapped molecular space. What do you think about light-powered biomanufacturing? Tell us in the comments.