Imagine watching a wound knit itself closed, not over weeks, but over hours, as a printer lays down living threads of tissue that bloom into skin. That is the promise galvanizing labs racing to merge biology with precision engineering. The problem is stark: severe burns, chronic ulcers, and surgical defects still depend on grafts that are scarce, painful to harvest, and slow to heal. The counter-move is audacious – print skin on demand that looks, feels, and behaves like the real thing, complete with vessels, pigment, and strength. It’s not science fiction anymore; it’s a series of quietly spectacular breakthroughs learning to speak the body’s native language.

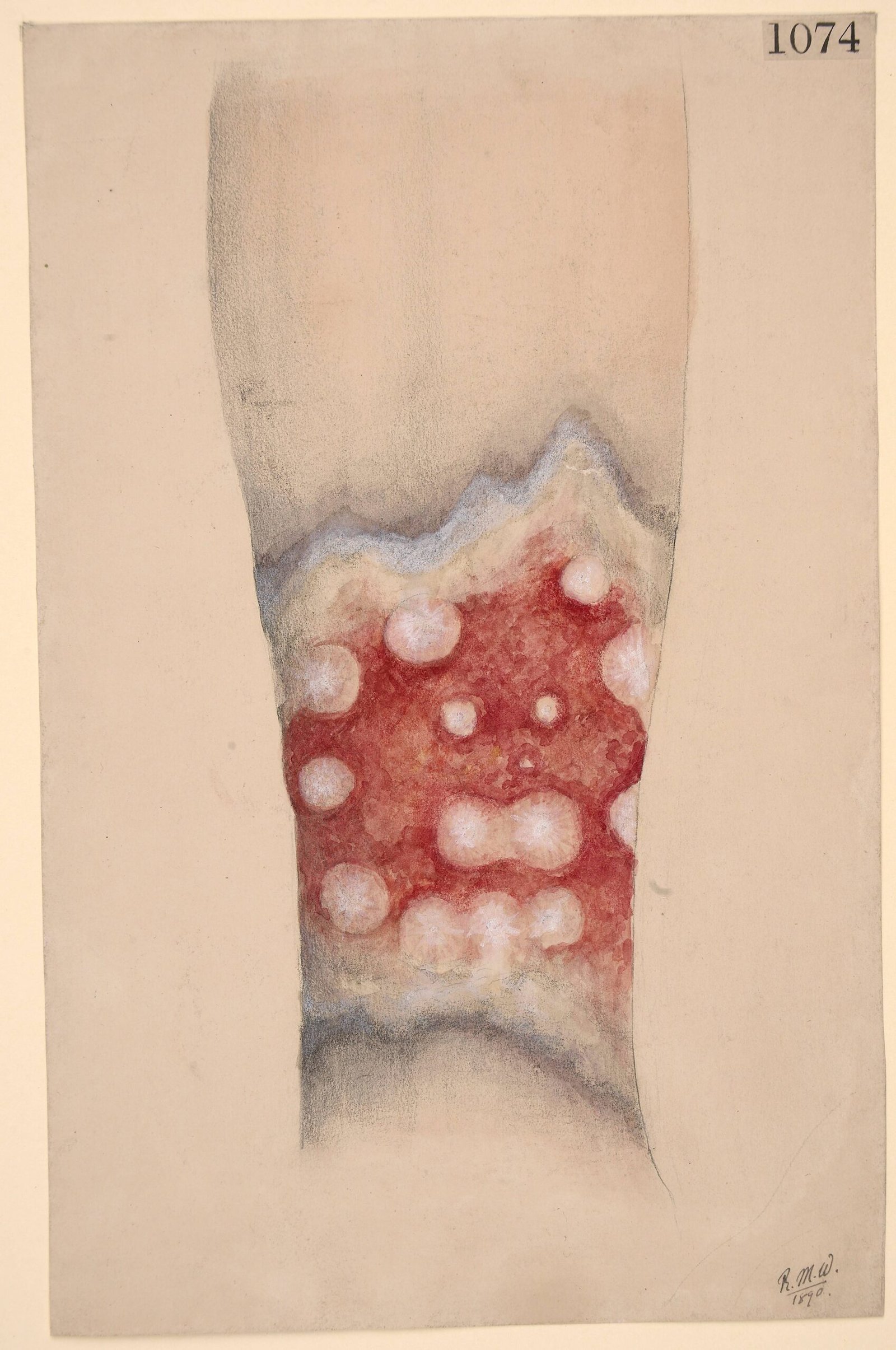

The Hidden Clues

The Hidden Clues (image credits: Wikimedia)

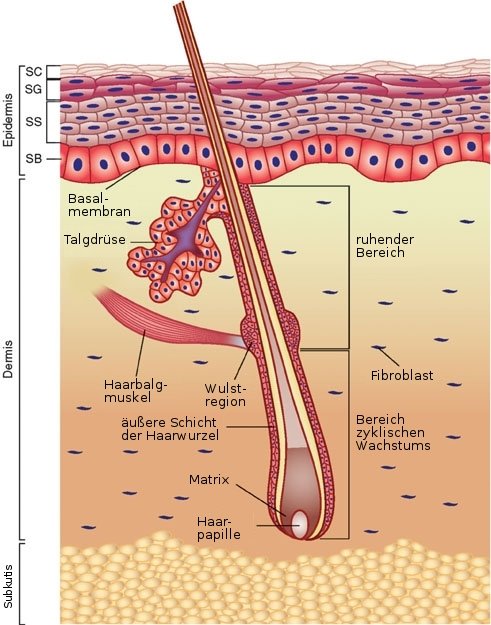

Here’s the surprising part: skin isn’t just a protective cover, it’s a living circuit of cells, proteins, fluids, and signals that never stop talking. Scientists study those signals – growth factors, mechanical cues, and electric fields – to choreograph how printed cells assemble, migrate, and mature. Think of it like jazz rather than sheet music: the bioink provides the melody, but the microenvironment improvises harmonies that make tissue come alive.

Decoding that microenvironment is the hidden engine of progress. Teams map how collagen fibers align under tension, how oxygen gradients nudge vessels to sprout, and how immune cells decide whether to calm inflammation or fan the flames. By translating these clues into printer paths and material recipes, researchers are nudging inert gels to behave like healing skin rather than sterile scaffolds.

From Ancient Tools to Modern Science

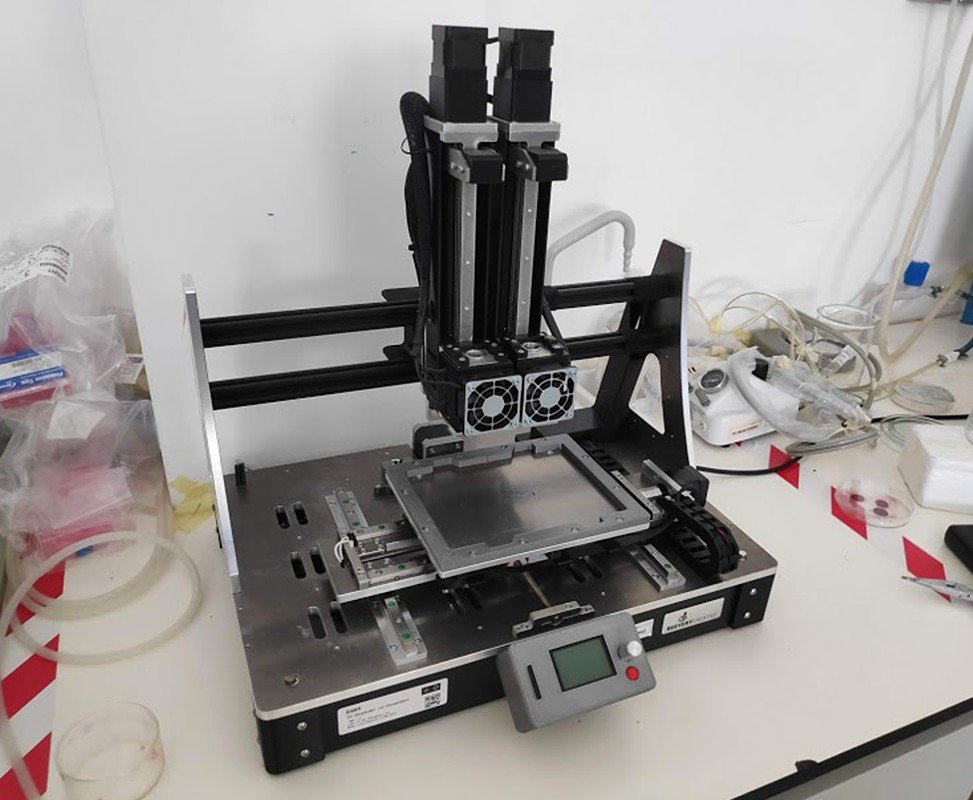

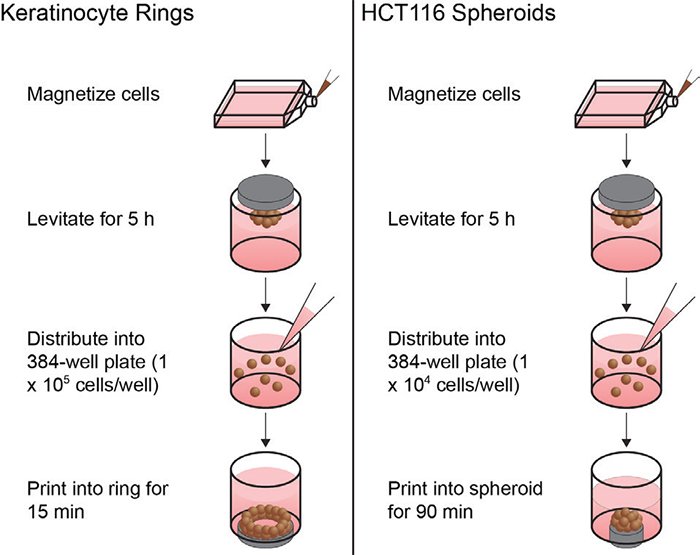

Skin grafting has roots in centuries-old surgical tricks, but it still hinges on donor tissue and careful suturing. Bioprinting shifts the paradigm by layering cell-laden hydrogels with the same deliberateness a mason lays bricks, except the bricks are alive. Early systems drew inspiration from inkjet and extrusion printers, then evolved into microfluidic printheads that can switch cell types on the fly.

Laser-assisted approaches add another leap, depositing tiny droplets with remarkable precision while preserving cell viability. Meanwhile, volumetric bioprinting shapes entire structures in seconds using light patterns, like sculpting a statue inside a block of gel. The toolbox is no longer a single “printer,” but a family of machines tuned for different pieces of the skin puzzle.

Printing the Building Blocks

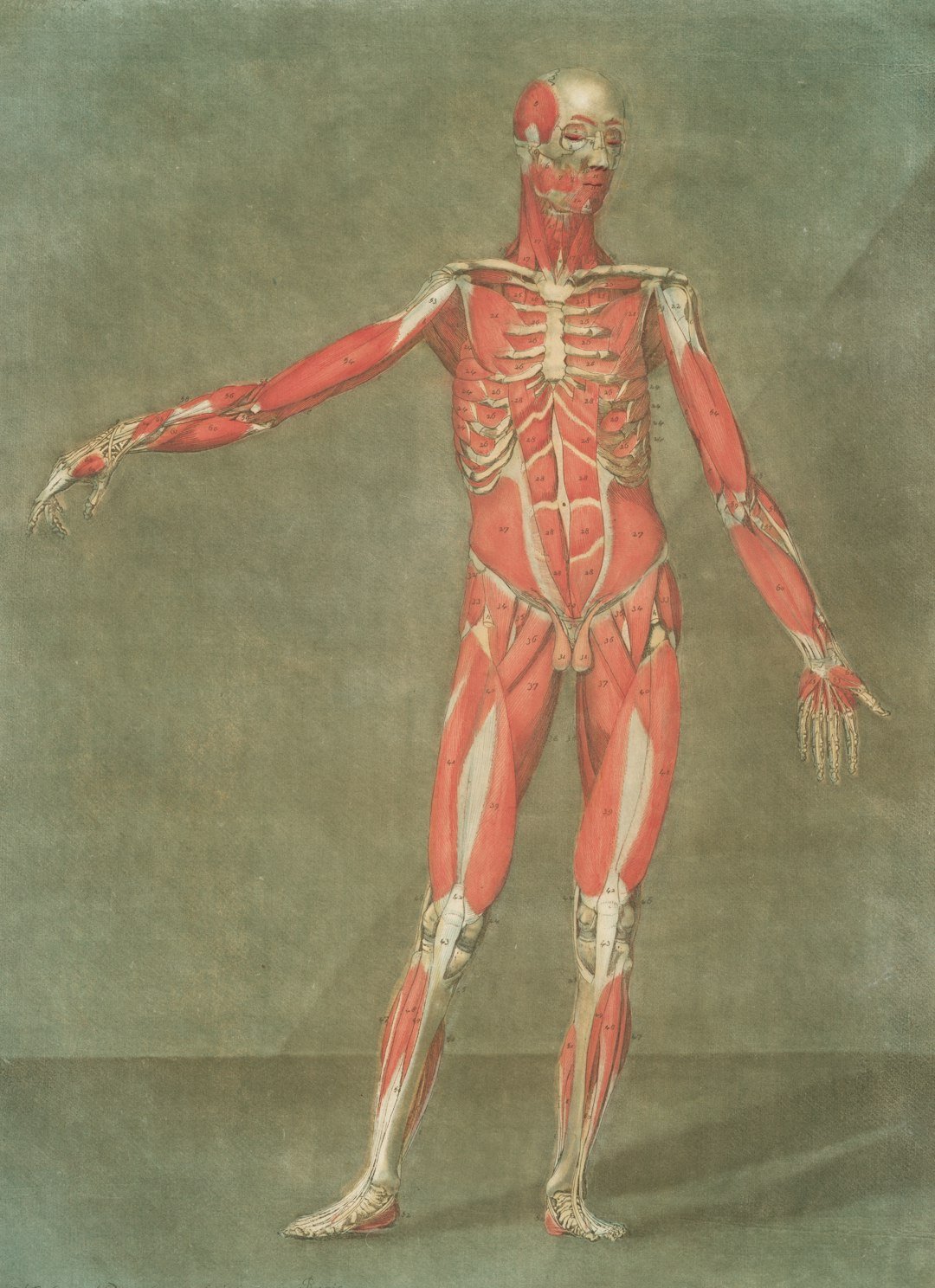

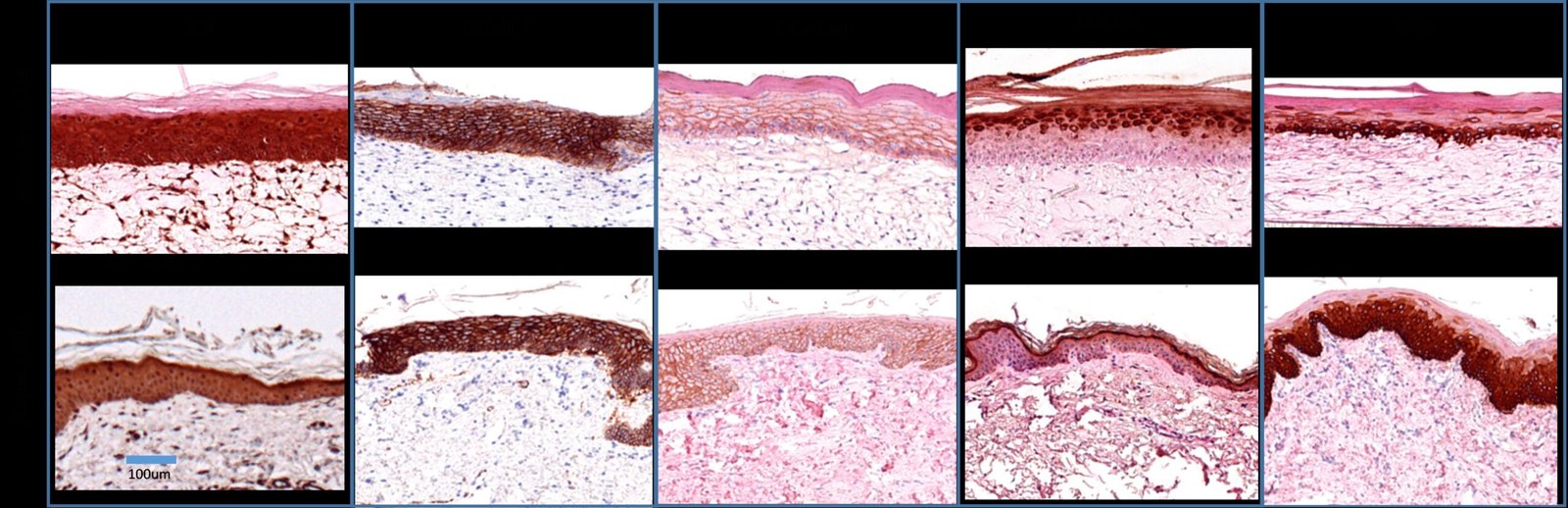

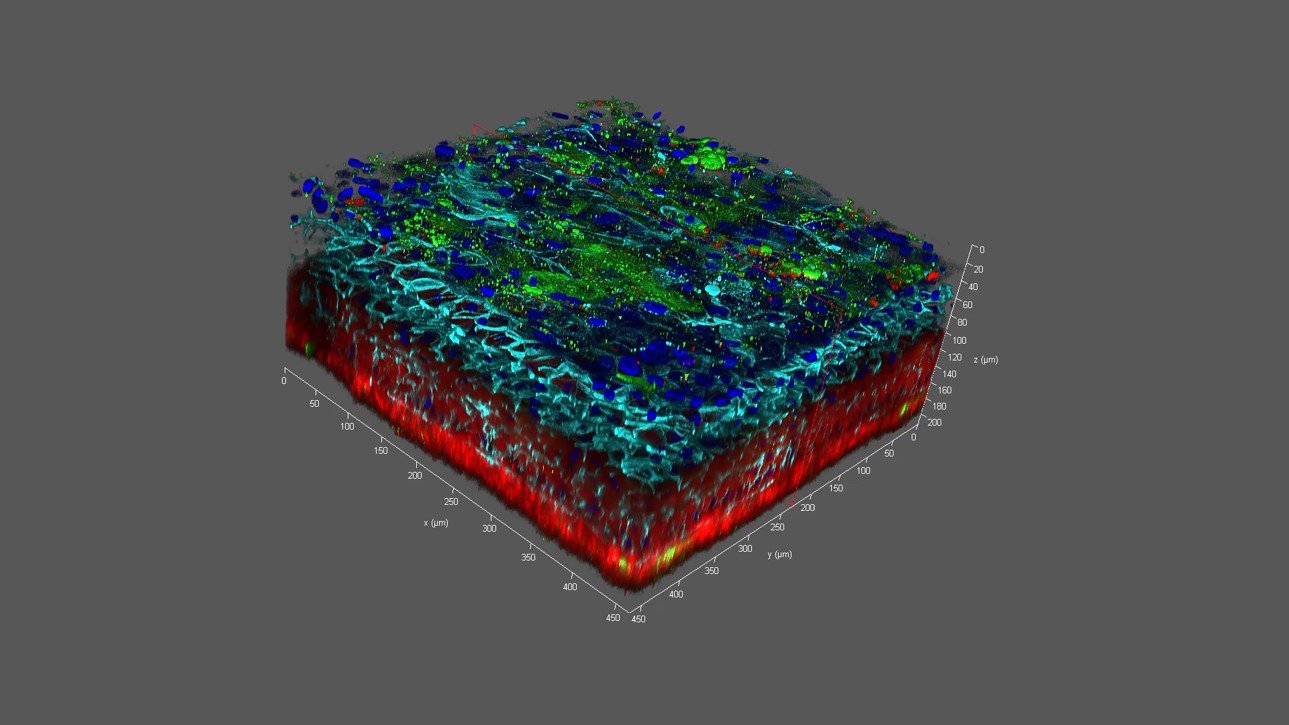

Bioinks are the unsung heroes, made from collagen, gelatin, fibrin, hyaluronic acid, and decellularized extracellular matrix that preserve the body’s subtle cues. Into these soft matrices go keratinocytes for the epidermis, fibroblasts for the dermis, and melanocytes for pigment, often joined by endothelial cells that form the earliest capillaries. The goal is a multi-layer stack that mimics the skin’s barrier on top and its supportive bed below.

Crosslinking – chemically or with light – gives the printed construct enough strength to hold shape while remaining hospitable to cells. Additives like growth factors and peptide motifs act like signposts, telling cells where to attach and when to divide. Over days, these quiet instructions turn an orderly print into a living sheet that resembles native tissue more and more.

Vessels, Nerves, and the Oxygen Problem

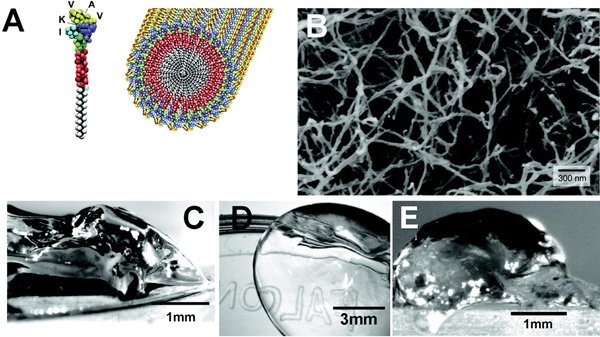

Vascularization is the make-or-break step because cells starve without oxygen diffusing more than a hair’s breadth. To beat that limit, engineers print sacrificial channels that dissolve into microtunnels, or co-print endothelial and support cells that self-assemble into capillary networks. Some groups perfuse printed skin in bioreactors, feeding nutrients through those channels until they connect with the body after grafting.

Innervation is the next frontier. Nerves influence pain, touch, and even the way wounds heal, but guiding them into printed tissue is hard. Researchers are experimenting with nerve guidance conduits and gradients of neurotrophic factors, aiming for grafts that not only survive but feel like part of you.

Color, Texture, and the Human Match

Making skin that looks right is as important as making skin that lives. Melanocytes must be distributed evenly to avoid patchy pigmentation, and the dermal scaffold needs fibers aligned just so to prevent tight, shiny scars. Bioprinters now tune nozzle patterns and shear forces to coax collagen into familiar architectures.

Texture matters too. Engineers use microtopography – ridges and pores etched at tiny scales – to teach cells how to organize, a bit like grooves guiding a needle. The aim is personalized grafts that match a patient’s tone and contour, informed by three-dimensional scans and smart software that turn anatomy into print paths.

Printing Directly on Wounds

Printing Directly on Wounds (image credits: Wikimedia)

In situ bioprinting takes the lab to the bedside. Portable devices can scan a wound, compute its topography, and lay down layers of bioink tailored to the defect. It’s like icing a cake, except the frosting is alive and designed to knit with the patient’s tissue.

This approach reduces handling, shortens the time cells spend outside a nurturing environment, and may cut infection risk. Surgeons imagine a near-future workflow: debride, scan, print, and protect – then let biology do the rest. It’s bold, but early models in animals suggest the body is surprisingly willing to collaborate.

Pharmalabs and Testbeds

Not every printed skin ends up on a patient; many serve as testbeds for drugs, cosmetics, and wound-care products. These standardized tissues help screen compounds before human trials, potentially sparing volunteers and catching problems earlier. Because the constructs can include pigment cells, vessels, and even immune components, they offer a richer picture than flat cell cultures.

Industry interest is practical: better models may reduce costs and failed trials. A handful of companies cultivate bioprinted skin platforms with defined recipes and quality controls so results are comparable across studies. That consistency matters when regulators and clinicians want evidence that translates from bench to bedside.

Why It Matters

Severe burns and chronic ulcers affect hundreds of thousands of people each year, and the human toll is heavy – pain, infection, repeated surgeries, and long recoveries. Traditional autografts require harvesting healthy skin, which adds new wounds and extends hospital stays. Donor grafts can help, but availability is limited and long-term integration is uneven.

Bioprinted skin targets those gaps with a scalable, patient-matched solution. It promises shorter operating times, fewer donor sites, and grafts designed for the job, whether that’s a tough joint or a delicate facial area. If it works as intended, the ripple effects could include lower costs, faster mobility, and a better chance to return to everyday life.

- Autografts remain the current gold standard, but they create new injuries to heal.

- Bioprinting aims to deliver larger, customized grafts without donor-site pain.

- Engineered vascular networks are key to moving from lab prototypes to clinical reliability.

The Future Landscape

What comes next feels both exhilarating and stubbornly hard. Researchers are integrating sweat glands for thermoregulation and experimenting with hair follicle organoids to restore natural appearance. Others are exploring gene-edited autologous cells to correct inherited skin disorders before printing, blending cell therapy with tissue engineering.

Safety and scale will decide winners. Manufacturing must meet medical-grade standards, from sterile workflows to traceable cell sources, and printers need to produce consistent grafts at hospital speed. Expect hybrid teams – surgeons, bioengineers, materials scientists – training together so operating rooms become part biology lab, part robotics suite.

Global Perspectives

Burn care differs widely around the world, and that shapes how bioprinting may roll out. High-resource hospitals might adopt in situ printers first, while centralized facilities could ship ready-to-use grafts to regional centers. Low-resource settings may benefit from ruggedized, cartridge-based systems that minimize cold-chain dependence.

Standards will matter across borders. Shared protocols for bioinks, sterility, and testing could help avoid a patchwork of approvals that slows progress. Collaborative trials spanning multiple countries may answer the most urgent question: which printed constructs actually improve patient outcomes in real clinics?

Roadblocks and Real Talk

Biology is messy, and no printer can wish away the immune system’s skepticism. Even autologous cells can misbehave, and scar formation remains a stubborn foe. Mechanical strength, elasticity, and long-term durability must match the daily abuse skin takes from movement, sunlight, and microbes.

Cost is another hurdle. Bioinks, cell expansion, and skilled staff aren’t cheap, and insurers will want hard evidence before covering new procedures. Still, compared with the cascade of surgeries and rehab many patients endure, a reliable printed graft could be the more humane and ultimately economical option.

Conclusion

If this field resonates with you, there are simple ways to help it grow responsibly. Support burn centers and wound-care programs that participate in rigorous clinical studies, because patient data drives safer innovation. If you’re a student or educator, look for community lab programs that teach bioprinting fundamentals and ethics, not just the hype.

For the rest of us, staying curious matters: read beyond headlines, ask how trials are designed, and back nonprofits that make reconstructive care accessible worldwide. Progress in bioprinting isn’t just about machines – it’s about people willing to build, test, and iterate with care. When living tissue can be printed on demand, what kind of healing do you want to see?

Suhail Ahmed is a passionate digital professional and nature enthusiast with over 8 years of experience in content strategy, SEO, web development, and digital operations. Alongside his freelance journey, Suhail actively contributes to nature and wildlife platforms like Discover Wildlife, where he channels his curiosity for the planet into engaging, educational storytelling.

With a strong background in managing digital ecosystems — from ecommerce stores and WordPress websites to social media and automation — Suhail merges technical precision with creative insight. His content reflects a rare balance: SEO-friendly yet deeply human, data-informed yet emotionally resonant.

Driven by a love for discovery and storytelling, Suhail believes in using digital platforms to amplify causes that matter — especially those protecting Earth’s biodiversity and inspiring sustainable living. Whether he’s managing online projects or crafting wildlife content, his goal remains the same: to inform, inspire, and leave a positive digital footprint.